ASO Liner Antistatic Type

Major features

| Clean

| Highly clean

| Standard size

| Sterilized

| Antistatic

| UV protection

|

Request a quote

Contact us

Overview

With recent developments in polymer chemistry and modernization of production processes, explosions, fires, and other industrial accidents are often caused by static electricity in factories or workplaces.

ASO Liner Antistatic Type, an antistatic round-bottomed inner bag for open drums, is a safety-sensitive inner bag that, unlike conventional antistatic types, satisfies the surface-specific resistance requirement of 1011Ω or below.

ASO Liner Antistatic Type, an antistatic round-bottomed inner bag for open drums, is a safety-sensitive inner bag that, unlike conventional antistatic types, satisfies the surface-specific resistance requirement of 1011Ω or below.

-

An antistatic agent (non-ionic surfactant) is kneaded into low-density polyethylene resin in the manufacturing process, allowing the product to have an antistatic effect over a long duration.

-

In order to prevent seasonal differences in antistatic effect, we have developed seasonal production manuals to ensure that a stable antistatic effect is maintained for safe use throughout the year.

-

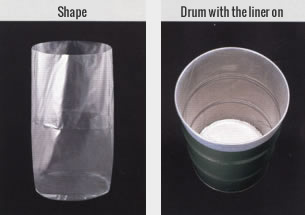

The completely cylindrical inner bag fits a drum well and does not break, because of an "air hammer phenomenon" during transportation or handling.

-

You just have to replace the liner after use, so that you can use the same drum with different materials. You no longer need to wash drums as is conventionally done, which significantly reduces the cost of washing drums. After filling the inner bag with a material, you can stir with a blender or extract with a machine.

Surface-specific resistance (Ω)

* Test method: JIS K-6911

* The above figures are measured, not guaranteed, values.

* The above figures are measured, not guaranteed, values.

Size/Specifications

* To fold back the liner over an open drum, you should select the 940 mm high liner.